Hello my Friends, Do you know We can make metals stronger so it could last long much more. There are few special methods which helps in achieving so. They are called general processing techniques and they play a very important role in the metalworking world.

Heat treatment is the process of making metal stronger. This practice is performed by high-temperature heating and cooling the metal in a peculiar method If the metal is heated and cooled in a specific way it becomes stronger, more resistant to wear. This makes it much more resistant to damage than raw metal is. This is employed in several fits like cars, air-craft where we require strong material.

Surface treatment This technique is used to enhance the quality of metal. Here, a specific layer is applied on the surface of metal. This layer protects the metal from rust -rust is when iron gets eaten away by water and air. The layer also contributes to the galvanized metal tubing as a whole gaining greater strength. A harder surface eludes to the metal being more scratch and dent resistant than ever. Spend time on this (if items will be used heavily, like tools and machinery parts)

Easy and Accurate Metalwork

Efficiency and accuracy are two things that can never be compromised upon in metal working. Efficiency is doing things fast and with the least amount of waste while Accuracy has been to do it right without error. For this reason, many companies are turning to specialist machinery and innovative technology for optimum results. This contributes to less time consuming and quality products developed from the above-mentioned methods.

CNC machining is an example of these advanced techniques.

CNC: Computer Numerical Control. This method involves using computers to tell the machines responsible for cutting and shaping round metal stock how to operate. Computer: Workers use a computer to get exact cuts on many of the parts, so they look exactly alike each time one is made. Car and electronics companies know this is critical for machinery requiring tight tolerances in how they fit together.

Much of what was done in metalworking is now done by automatic" machines. This means that the work need not be done completely by hand, and thus it is a time saver, so we can also see metal products with better efficiency. In other words, with automation or machines taking care of performing tasks, the likelihood for human error decreases. This allows manufacturing huge amounts of carbon sheet metal products by HanWu at short notice without compromising on quality levels.

High-Quality Metal Products

High Quality Products: Making metal products requires a certain level of quality that must be achieved. Secondly, quality refers to the durability of a product. This is how many companies resort to professionals methods of production that the level and quality, required for strict rules.

Another important way to preserve high quality is by using a process called as Quality Control. That then involves a detailed examination of the metal and testing during every stage of its manufacture. Implemented for finding any problems or defects at the initial level to reduce defect fixing costs, quality control. So the end product comes very good and maintains the highest quality levels. Without QC, these goods could be shipped to end users which can result in safety hazards or products which do not work.

Precision machining is another technique. It is a way of making parts that match together precisely, similar to how special machines build intricate shapes. To produce the most precise metal products possible, precision machining is a necessity for intricate projects. And this is true, so the smallest components must be perfect in order to integrate smoothly on a higher level. All of this accuracy is essential for items such as engines and electronic devices.

A Metallurgist in Your Solution

If you require metal for different purposes such as buildings, car or airplanes; companies can help to cater your specific needs. what this text will probably be doing, helping you search out all the fellows which have metal you may need on your mission.

Metal cutting is one such option. This involves the introduction of metal sheets cutting into specified forms and measurement for different purposes. This cutting can be done in many ways: laser cutters for a fine, smooth surface or water jets that use high-pressure water to separate the metal. Both are useful in their own ways, and companies use one or the other as most suitable for work.

Metal Bending

Another service that companies provide is metal bending. This builds the metal in to different shapes using special machines. This is because a lot of metal components have to be lanced or bent so they will go into the end product. This makes parts that are well-suited for numerous applications, from furniture to machinery.

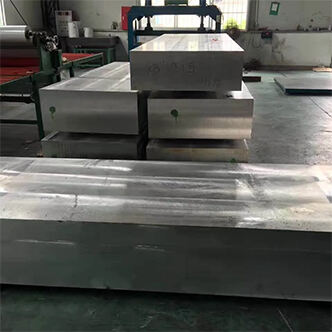

Raw Materials Formed Into Precision Parts

Production of finished parts out of raw metal is a process that demands unique ways to be applied with the help of high-tech machinery. Manufacturing companies who work with metal are changing the status quo by using a mix of well established and modern techniques to remain ahead of competitors in delivering exceptional results. This flexibility in the mix enables an effective response to different manufacturing requirements.

Some examples would be the ancient technique of forging where metal is heated then molded using either a hammer or machine. Open die and closed dies are two types of wrought methods for metal forging. Every method has its own benefits and is performed on different kinds of metal products.

In comparison, additive manufacturing is a newer method where 3D printers are used to build metal parts layer-by-layer. This makes it possible to produce intricate designs and bespoke parts which may be challenging to manufacture via conventional methods. Additive manufacturing is interesting just because... for the first time, opportunities were created to receive specific spare parts made of metal.