+86 13075358901

WhatsApp| Place of Origin: | Shandong |

| Brand Name: | Hanwu |

| Model Number: | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920,C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300,C12500,C14200,C14420,C14500,C14510,C14520,C14530,C17200,C19200,C21000,C23000,C26000,C27000,C27400,C28000,C33000,C33200,C37000,C44300,C44400,C44500,C60800,C63020,C65500,C68700,C70400, C70620,C71000,C71500,C71520,C71640,C72200 T1,T2,T3,TU1,TU0,TU2,TP1,TP2,TAg0.1, |

| Certification: | ISO ,BV ,SGS, CE |

| Minimum Order Quantity: | 1 tons |

| Packaging Details: | Export standard package: bundled wooden box, suit for all kinds of transport,or be required. |

| Delivery Time: | 15-20 days or subject to the clients' requirement and quantity |

| Payment Terms: | 30%TT for deposit, 70% balance before shipment or LC at sight |

| Supply Ability: | 20000 tons per month |

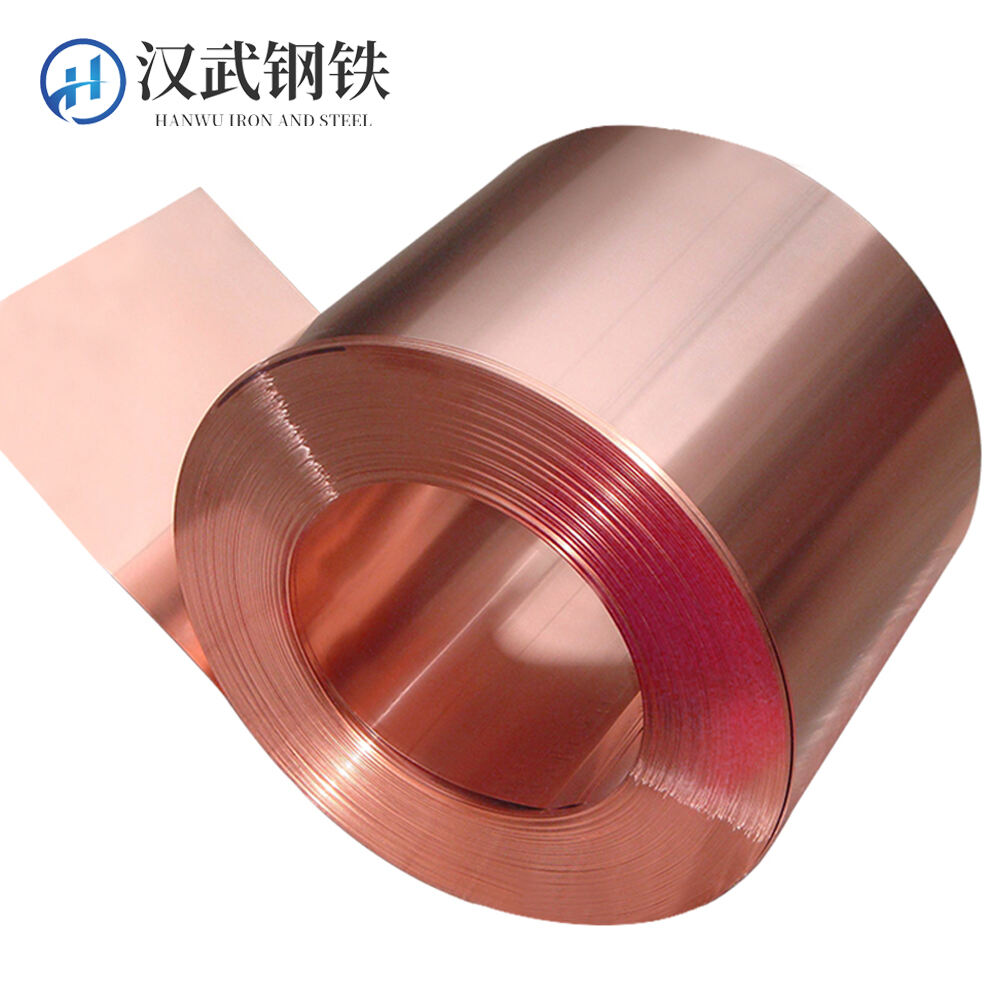

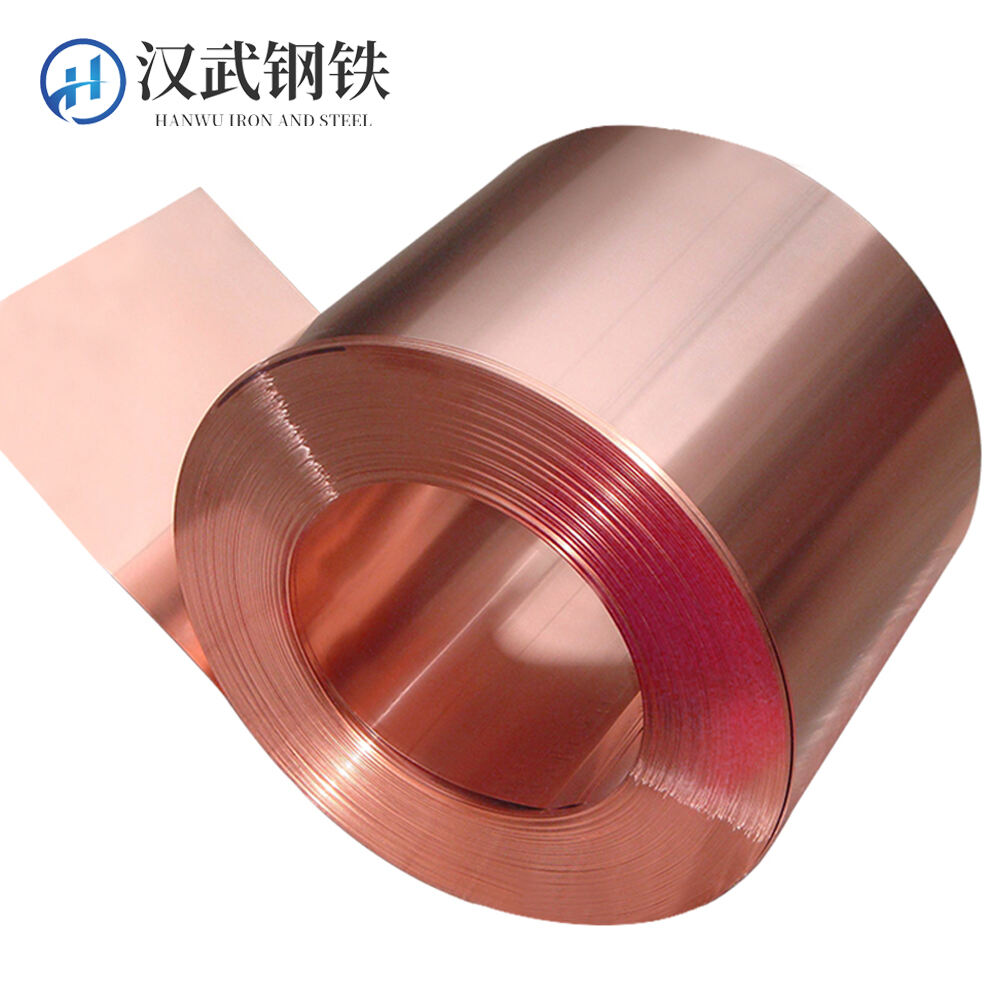

Copper Coil, is widely known for its architectural applications whereas the familiar green patina appearance is acheived when exposed to the elements.Copper Coil have excellent hot or cold workability and is ductile when heated. Copper Coils are also noted for their high electrical and thermal conductivity, and good corrosion resistance.

Product Parameters

| Thickness | 0.1-300mm, or customized | Length | 100-12000mm, or customized |

| Width | 10-3000mm, or customized | Standard | ASTM, AISI, JIS, GB, DIN, EN |

| Brand | C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910, C10920, C10930,C11000, C11300, C11400, C11500, C11600, C12000, C12200, C12300, C12500, C14200,C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000,C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800,C63020, C65500, C68700, C70400, C70620, C71000, C71500, C71520, C71640, C72200,T1, T2, T3, TU1, TU0, TU2, TP1, TP2, TAg0.1, ect. | ||

| Surface | Grinding, Polishing, Brightening, Oiling, Hair Thread, Brush, Mirror, Sandblasting or Processing As Required | ||

| Certification | ISO, SGS, BV | Payment Method | FOB, CRF, CIF, EXW Acceptable |

| Port of Loading | Any port in China | Delivery Time | Received 30% after deposit 7-15 working days |

Chemical Composition

| Copper+SilverWith Ag: | TinSn: | ZincZn: | LeadPb: | NickelIt is: | IronFe: |

| ≥ 99.90 | ≤ 0.002 | ≤ 0.005 | ≤ 0.005 | ≤ 0.005 | ≤ 0.01 |

| AntimonySb: | SulphurS: | ArsenicAs: | BismuthBi: | OxygenO: | PhosphorusP: |

| ≤ 0.002 | ≤ 0.005 | ≤ 0.002 | ≤ 0.002 | ≤ 0.01 | 0.005~0.012 |

Mechanical Properties

| Tensile StrengthKb (MPa): | ElongationD10 (%): | Hardness: |

| 245~345 | ≥ 8 | 75~120HV |

Scope of Application

| Uses And Applications of Copper | |

| Power Industry | Power transmission such as line cables, transformers, switches, plug components and connectors, etc.; motor manufacturing such as stator, rotor, shaft head and hollow wire, etc.; communication cables and residential electrical lines also need to use a large number of copper wires. |

| Electronic Industry | Electric vacuum devices such as high-frequency and ultra-high-frequency emission tubes, catheters, magnetrons, etc., they need high-purity oxygen-free copper and dispersion-strengthened oxygen-free copper. Copper printed circuits require a large amount of copper foil and copper-based brazing material. Integrationin the circuitCopper replaces aluminum in silicon chips for interconnect lines and lead frames. |

| Energy and Petrochemical Industry | The main condenser tube plate and condenser tube of the energy industry thermal power plant are made of brass, bronze or cupronickel. Solar heaters are also often manufactured using copper tubing. Petrochemical industry copper and many copper alloys, used in large quantities to manufacture contact corrosionVarious media containers, piping systems, filters, pumps and valves, various evaporators, heat exchangers and condensers, etc. |

| Transportation Industry | In the shipbuilding industry, copper alloys include aluminum bronze, manganese bronze, aluminum brass, gunmetal (tin zinc bronze), white copper and nickel copper alloy (Monel alloy), etc. are all standard materials for shipbuilding. In warships and merchant ships, copper and copper alloys are generally used as aluminum bronze propeller,Bolts, condenser tubes, rivets, copper coated paint, etc. In the automotive industry, copper and copper alloys are mainly used in radiators, brake system pipelines, hydraulic devices, gears, bearings, power distribution and power systems, brake friction plates, washers and various joints,Accessories and trims, etc. The motors, rectifiers and control, braking, electrical and signal systems on railway trains also rely on copper and copper alloys to work. In addition, the electrification of railways requires a large amount of copper and copper alloys.in the aircraftCopper for wiring, hydraulic, cooling and pneumatic systems, aluminum bronze tubing for bearing retainers and landing gear bearings, and diamagnetic copper alloy for navigation instruments. |

| Mechanical and Metallurgical Industries | In addition to a large number of copper used in motors, circuits, hydraulic systems, pneumatic systems and control systems in mechanical engineering, various transmission parts and fixing parts, such as cylinder liners, connectors, fasteners, gears, twisting parts, etc., all Need to reduce wear and lubrication with copper or copper alloy.The key component in continuous casting technology of metallurgical equipment-crystallizer, mostly made of high strength and high thermal conductivity copper alloy such as chromium copper, silver copper, etc., and the vacuum arc furnace and electroslag furnace water-cooled crucible in electrometallurgy are made of copper pipe, and various induction heatingThe induction coils are all made of copper tubes or special-shaped copper tubes, which are cooled by water. |

| Light Industry | Copper and copper alloy can be used in the manufacture of air conditioner heat exchanger, watch movement, paper machine mesh, roller, printing copper plate, fermentation tank lining, distillation pot, building decoration components, etc. |

| Emerging Industries and High-tech Fields | Copper is also used in emerging industries and high-tech fields, such as superconducting alloy jackets, ultra-low temperature medium containers and pipelines, rocket engine cooling village, high-energy accelerator magnet windings. |